Öncü Otomasyon Endüstriyel Makina Sistemleri San. Ve Tic. Ltd. Şti.

+90 506 880 86 59 | İvedik OSB Mah. 1553 Sok. No:15 Yenimahalle/ANKARA

Öncü Otomasyon Endüstriyel Makina Sistemleri San. Ve Tic. Ltd. Şti.

+90 506 880 86 59 | İvedik OSB Mah. 1553 Sok. No:15 Yenimahalle/ANKARA

One of the ground grouting techniques is cement grouting. It is applied by mixing the active substances such as cement, water and bentonite with certain ratios and grout- ing them into the spaces under pressure.

The main element here is to apply the grouting pressure and grouting speed according to the structure of the ground of the injected volume.

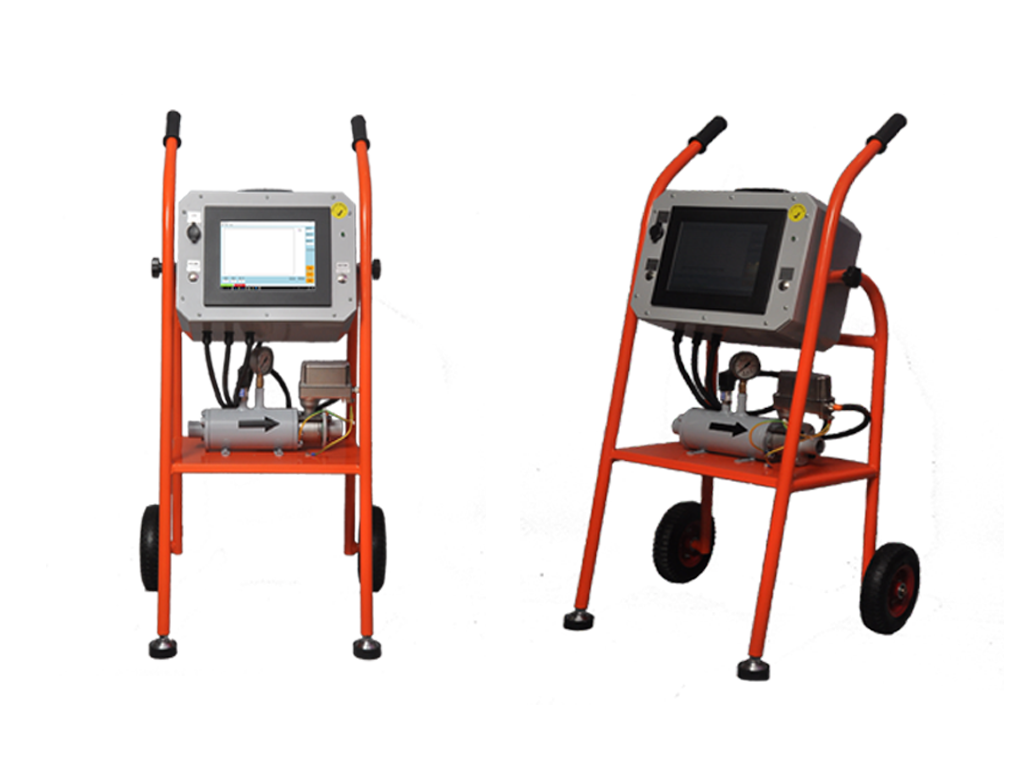

"KRAFTER" makes the application controllable, traceable and reportable

FLOW: Measurement is made with the help of electro-mag- netic flow meters.

Wear resistant ceramic interior Measurement accuracy = 0-0.5 l / s Measuring temperature = -50 ° C 50 + 70 ° C Pmax = 50bar

PRESSURE: High-precision pressure measurement with diaphragm

Measurement accuracy = 100mbar-100bar Measuring temperature = -40 ° c °. + 125 ° c Accuracy: 0.1 ± 0.10 / 0.05% FS

SUPPLY: It works with 220 VAC 3A mains voltage.

It has a structure which can continue for 30 minutes with the help of built-in ups in energy cuts.

(high protection against energy fluctuations)

Display Features

DISPLAY: Size 10 "LED

Resolution 800 x 600 @ 60Hz Touch 5 wire resistive memory 64gb ssd disk

Working temperature -10 ° C ° + 60 ° C

Humidity values 20% ~ 90% WITHOUT INTENSITY

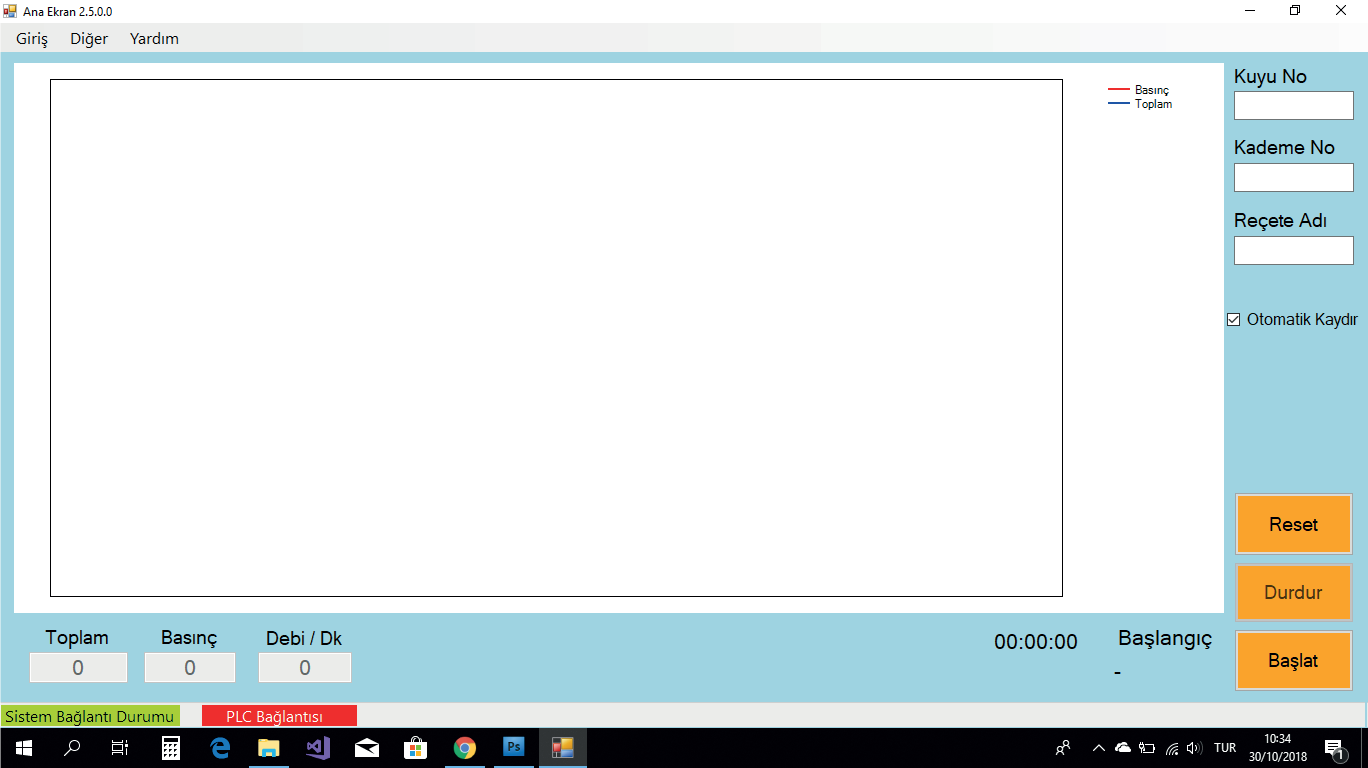

SOFTWARE: The well name allows you to record with step and mix references and to watch these recordings in real time.

Flow rate, pressure and flow / lt are recorded instantly. At the time of recording, the user can select 1 minute to 60 minutes and the corresponding stream id is written to the database. During recording, flow rate and pressure graph are monitored with time reflection from the monitoring screen.

SOFTWARE VERIFICATION: Flow and pressure are calibrated at the factory. Products can be made by the user if the validation due to wear due to usage is needed.The menu is protected by password and kept closed for general access.

The menu is protected by a password and kept publicly accessible

REPORTING: The availability of past reports allows easier access by searching with start date, end date, well name, step and recipe references.

The report consists of three sections as visual graph, summary information and detail information as PDF. It provides the user with the ability to understand the work done at first glance and to see the detail when desired.

REPORT OUTPUT: The reports can be viewed via “KRAFTER” and also can be transferred to external environment via the USB port.

If desired, "KRAFTER" can also be printed in real time with the defined printer. The printer can be any brand or model that the user will specify.